Air Compressor Suppliers in West Bengal

BAC Compressors is a leading dealer of a wide range of air compressors in West Bengal. BAC offers customized compressor designs for industrial, domestic, and agricultural applications. With decades of experience in compressor manufacturing, BAC has established itself as a trusted brand among air compressor dealers in India.

BAC offers a diverse range of products suitable for various applications, including inflating vehicle tires, spray painting, food processing industries, removing fine particles from heavy machinery, and farming operations of all types and sizes. We provide Reciprocating, Industrial, Screw, Portable, Borewell, and High-pressure air compressors at reasonable prices.

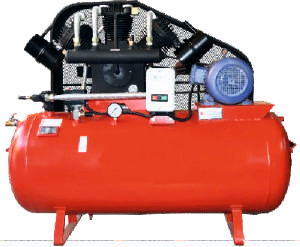

Industrial Reciprocating Air Compressors Suppliers in Kolkata

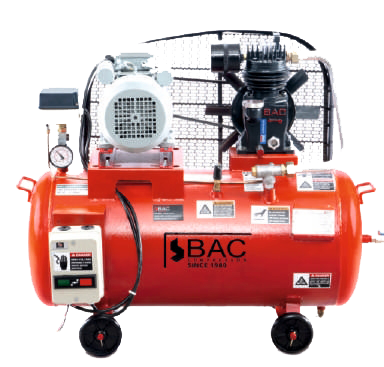

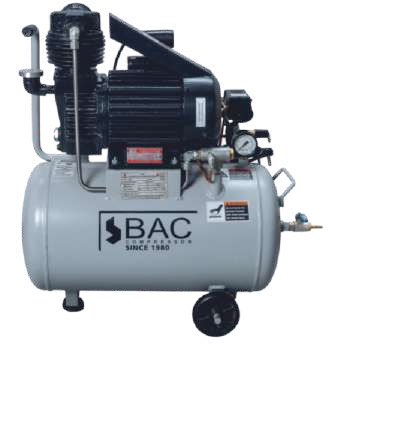

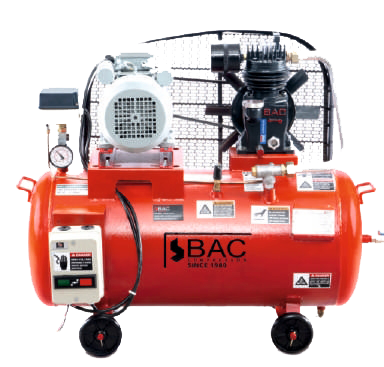

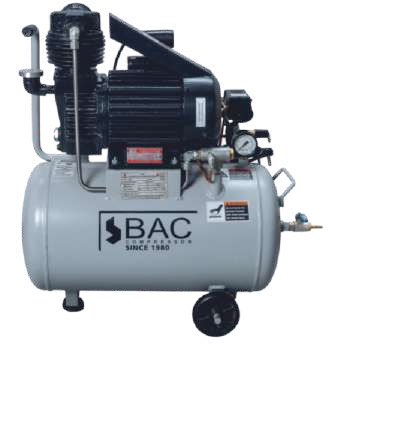

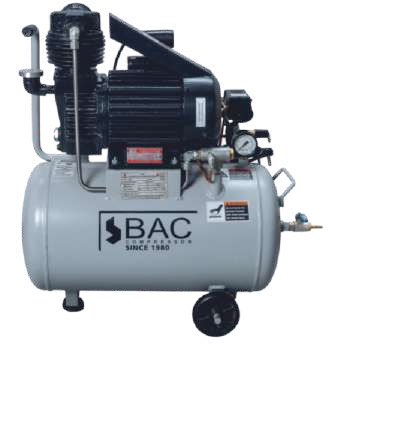

Monoblock Direct Driven Air Compressor

Single Cylinder Belt Driven Air Compressor

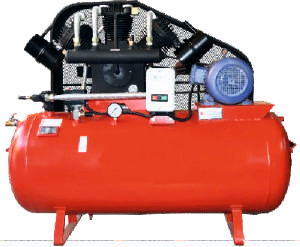

Double Cylinder Vertical Tank Air Compressor

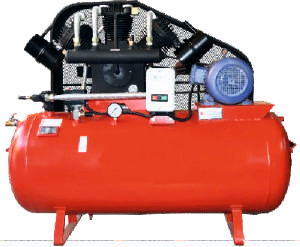

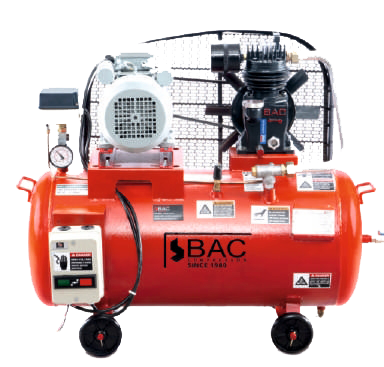

Double Cylinder Tank Mounted Air Compressor

Triple Cylinder Tank Mounted Air Compressor

Triple Cylinder Base Mounted Air Compressor

Spare Parts & Accessories

Refrigerant Air Dryer (20 CFM to 1000 CFM)

Air & Oil Filters (35 CFM to 777 CFM)

Auto Drain Valves (Low / High discharge & Float type)

Screw Air Compressor Dealers in Kolkata

Refrigerant Air Dryer (20 CFM to 1000 CFM)

BAC BD SERIES

SCREW COMPRESSOR TANK MOUNTED WITH DRYER

AIR END

Belt Driven and Coupling driven are available.

LOWER RUNNING SPEED

All BAC compressors run < 3000rpm which is much lower compared to our competitors. Large air-ends with lower running speed are more efficient than smaller air ends with higher running speeds because they supply more air for the same drive power. This results in higher bearing life, lower energy cost and reduces wear &tear on all the components.

COOLER

Bigger cooling surface area enhances the cooling of air and oil even at an ambient temperature of 55 °C. Smart programming allows cooling fan to start and stop at adjustable temperatures to minimize the energy cost of the motor. All BAC compressor coolers are positioned on top for natural flow of hot air.

PRE FILTERS

BAC compressors are equipped with pre-filter elements which prevents dust entry inside the canopy. This increases the suction filter element life and maintains the cleanliness inside the canopy.

LOWER NOISE

Canopy doors are lined up with high grade foam to keep the compressors as quiet as possible.

CONTROL PANEL

Our control system ensures reliable operation and protects your investment by continually monitoring the operational parameters. Some of the features include,

- Discharge pressure and temperature.

- Total run hours and load hours.

- Service due forall consumables.

- Safety features like high temperature cut-off, Low/high voltage cut-off, Direction control cut-off, High ampere cut-off, two phase protection.

- Accurate fault log monitor. (history of faults and current fault)

- Cooler fan start/stop temperature setting.

- Continuous unload shut-down timer.

SMART COMPRESSOR All compressors are fitted and supplied with loT device for remote monitoring at no extra cost.

LOWER OIL CARRY OVER

Oil separation is done by an efficiently designed tank through oil separation by impact and centrifugal force (OSB1C). This design allows lower pressure drop and increased life of separator element.

CANOPY

Our ergonomically designed canopy and layout allows quick and easy access to service personal with magnetic doors that can be removed in seconds.

SCREW AIR COMPRESSOR COUPLED DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping higher cfm/hp.

VFD SCREW AIR COMPRESSOR COUPLED DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

SCREW AIR COMPRESSOR BELT DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping and higher cfm/hp.

VFD SCREW AIR COMPRES - BELT DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

PERMANENT MAGNET MOTOR

SAVING MORE COST FOR YOU

REDUCING TOTAL OPERATIONAL COST OF AIR COMPRESSOR

The total cost consist of procurement, maintenance and energy cost in the life cycle of air compressor. The energy cost accounts for a considerable proportion. Energy consumption can be lowered by frequency conversion control system, thereby significantly reducing total cost of air compressor.

OTHER ADVANTAGES OF FREQUENCY CONVERSION CONTROL SYSTEM

Stable air pressure:Stepless speed regulation characteristics of frequency converter are utilized in frequency conversion screw air compressor. Pressure can be quickly adjusted and controlled through controller or PID regulator in inverter. Air pressure stability can be improved exponentially compared with upper and lower limit switch control of power frequency operation.

No impact on startup:Since inverter itself is a soft start device, maximum start current is about twice of rated current and the startup impact is small compared with power frequency startup which is generally several times higher than the rated current. The impact can gradually reduce impact on the power grid and the whole mechanical system.

Low noise and low wear:Since operation frequency during stable operation is smaller than power frequency, mechanical noise is lower and mechanical wear is low.

REFRIGERANT AIR DRYER

BAC Refrigerant Air Dryer models can be used for applications that require ISO 8573-1 Class 4 & Class 5 air quality. Automobile | Cement | Food processing | Injection Moulding | Packaging | Painting | Paper Mills Pet Bottle Industry | Pharmaceutical Industry | Pneumatic Control system | Pneumatic tools & Equipments Rice Sorting | Sand Blasting Textile Industry | Tire Inflation | Power Plants | Steel Plants

SILENT FEATURES

Service

Total modular canopy design, interchangeability, easy fitment of all components and the data from microcontroller ensures preventive maintenance and easy serviceability.

Designed for tropical conditions

Designed and manufactured to suit the high temperature condition by careful sizing of coolers, eveporators and selection of suitable refrigeration. components.

Low Pressure drop

The unique, Indigenously designed 3-in-1 evaporator facilitates low pressure drop lesser than 0.2 bar, while providing maximum heat transfer efficiency.

High Reliability

Reliability is ensured through superior quality parts like high grade, thicker copper tubes and processes like powder coating with 7 tank process etc, and through state-of-the-art safety controls and operation monitoring through unique microprocessor controllers.

AIR FILTERS

Purification of compressed air is needed because the air we breathe carries contaminants. Airborne particles, water, microbes and chemical gases enter compressors and in a compressed state these contaminants become concentrated and more destructive. In the compressed air system, hard particles assault equipment and piping. The result is damage to the system and generation of more particles. Examples of particles found in a compressed air system include desiccant dust, rust, pipe scale, metal oxides and dirt, which can be eliminated by applying proper filteration system.

Use “BAC” Genuine Spares & Accessories for Longer Life

Industrial Reciprocating Air Compressors Suppliers in Durgapur

Monoblock Direct Driven Air Compressor

Single Cylinder Belt Driven Air Compressor

Double Cylinder Vertical Tank Air Compressor

Double Cylinder Tank Mounted Air Compressor

Triple Cylinder Tank Mounted Air Compressor

Triple Cylinder Base Mounted Air Compressor

Spare Parts & Accessories

Refrigerant Air Dryer (20 CFM to 1000 CFM)

Air & Oil Filters (35 CFM to 777 CFM)

Auto Drain Valves (Low / High discharge & Float type)

Screw Air Compressor Dealers in Durgapur

Refrigerant Air Dryer (20 CFM to 1000 CFM)

BAC BD SERIES

SCREW COMPRESSOR TANK MOUNTED WITH DRYER

AIR END

Belt Driven and Coupling driven are available.

LOWER RUNNING SPEED

All BAC compressors run < 3000rpm which is much lower compared to our competitors. Large air-ends with lower running speed are more efficient than smaller air ends with higher running speeds because they supply more air for the same drive power. This results in higher bearing life, lower energy cost and reduces wear &tear on all the components.

COOLER

Bigger cooling surface area enhances the cooling of air and oil even at an ambient temperature of 55 °C. Smart programming allows cooling fan to start and stop at adjustable temperatures to minimize the energy cost of the motor. All BAC compressor coolers are positioned on top for natural flow of hot air.

PRE FILTERS

BAC compressors are equipped with pre-filter elements which prevents dust entry inside the canopy. This increases the suction filter element life and maintains the cleanliness inside the canopy.

LOWER NOISE

Canopy doors are lined up with high grade foam to keep the compressors as quiet as possible.

CONTROL PANEL

Our control system ensures reliable operation and protects your investment by continually monitoring the operational parameters. Some of the features include,

- Discharge pressure and temperature.

- Total run hours and load hours.

- Service due forall consumables.

- Safety features like high temperature cut-off, Low/high voltage cut-off, Direction control cut-off, High ampere cut-off, two phase protection.

- Accurate fault log monitor. (history of faults and current fault)

- Cooler fan start/stop temperature setting.

- Continuous unload shut-down timer.

SMART COMPRESSOR All compressors are fitted and supplied with loT device for remote monitoring at no extra cost.

LOWER OIL CARRY OVER

Oil separation is done by an efficiently designed tank through oil separation by impact and centrifugal force (OSB1C). This design allows lower pressure drop and increased life of separator element.

CANOPY

Our ergonomically designed canopy and layout allows quick and easy access to service personal with magnetic doors that can be removed in seconds.

SCREW AIR COMPRESSOR COUPLED DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping higher cfm/hp.

VFD SCREW AIR COMPRESSOR COUPLED DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

SCREW AIR COMPRESSOR BELT DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping and higher cfm/hp.

VFD SCREW AIR COMPRES - BELT DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

PERMANENT MAGNET MOTOR

SAVING MORE COST FOR YOU

REDUCING TOTAL OPERATIONAL COST OF AIR COMPRESSOR

The total cost consist of procurement, maintenance and energy cost in the life cycle of air compressor. The energy cost accounts for a considerable proportion. Energy consumption can be lowered by frequency conversion control system, thereby significantly reducing total cost of air compressor.

OTHER ADVANTAGES OF FREQUENCY CONVERSION CONTROL SYSTEM

Stable air pressure: Since stepless speed regulation characteristics of frequency converter are utilized in frequency conversion screw air compressor. Pressure can be quickly adjusted and controlled through controller or PID regulator in inverter. Air pressure stability can be improved exponentially compared with upper and lower limit switch control of power frequency operation.

No impact on startup: Since inverter itself is a soft start device, maximum start current is about twice of rated current and the startup impact is small compared with power frequency startup which is generally several times higher than the rated current. The impact can gradually reduce impact on the power grid and the whole mechanical system.

Low noise and low wear: Since operation frequency during stable operation is smaller than power frequency, mechanical noise is lower and mechanical wear is low.

REFRIGERANT AIR DRYER

BAC Refrigerant Air Dryer models can be used for applications that require ISO 8573-1 Class 4 & Class 5 air quality. Automobile | Cement | Food processing | Injection Moulding | Packaging | Painting | Paper Mills Pet Bottle Industry | Pharmaceutical Industry | Pneumatic Control system | Pneumatic tools & Equipments Rice Sorting | Sand Blasting Textile Industry | Tire Inflation | Power Plants | Steel Plants

SILENT FEATURES

Service

Total modular canopy design, interchangeability, easy fitment of all components and the data from microcontroller ensures preventive maintenance and easy serviceability.

Designed for tropical conditions

Designed and manufactured to suit the high temperature condition by careful sizing of coolers, eveporators and selection of suitable refrigeration. components.

Low Pressure drop

The unique, Indigenously designed 3-in-1 evaporator facilitates low pressure drop lesser than 0.2 bar, while providing maximum heat transfer efficiency.

High Reliability

Reliability is ensured through superior quality parts like high grade, thicker copper tubes and processes like powder coating with 7 tank process etc, and through state-of-the-art safety controls and operation monitoring through unique microprocessor controllers.

AIR FILTERS

Purification of compressed air is needed because the air we breathe carries contaminants. Airborne particles, water, microbes and chemical gases enter compressors and in a compressed state these contaminants become concentrated and more destructive. In the compressed air system, hard particles assault equipment and piping. The result is damage to the system and generation of more particles. Examples of particles found in a compressed air system include desiccant dust, rust, pipe scale, metal oxides and dirt, which can be eliminated by applying proper filteration system.

Use “BAC” Genuine Spares & Accessories for Longer Life

Industrial Reciprocating Air Compressors Suppliers in Siliguri

Monoblock Direct Driven Air Compressor

Single Cylinder Belt Driven Air Compressor

Double Cylinder Vertical Tank Air Compressor

Double Cylinder Tank Mounted Air Compressor

Triple Cylinder Tank Mounted Air Compressor

Triple Cylinder Base Mounted Air Compressor

Spare Parts & Accessories

Refrigerant Air Dryer (20 CFM to 1000 CFM)

Air & Oil Filters (35 CFM to 777 CFM)

Auto Drain Valves (Low / High discharge & Float type)

Screw Air Compressor Dealers in Siliguri

Refrigerant Air Dryer (20 CFM to 1000 CFM)

BAC BD SERIES

SCREW COMPRESSOR TANK MOUNTED WITH DRYER

AIR END

Belt Driven and Coupling driven are available.

LOWER RUNNING SPEED

All BAC compressors run < 3000rpm which is much lower compared to our competitors. Large air-ends with lower running speed are more efficient than smaller air ends with higher running speeds because they supply more air for the same drive power. This results in higher bearing life, lower energy cost and reduces wear &tear on all the components.

COOLER

Bigger cooling surface area enhances the cooling of air and oil even at an ambient temperature of 55 °C. Smart programming allows cooling fan to start and stop at adjustable temperatures to minimize the energy cost of the motor. All BAC compressor coolers are positioned on top for natural flow of hot air.

PRE FILTERS

BAC compressors are equipped with pre-filter elements which prevents dust entry inside the canopy. This increases the suction filter element life and maintains the cleanliness inside the canopy.

LOWER NOISE

Canopy doors are lined up with high grade foam to keep the compressors as quiet as possible.

CONTROL PANEL

Our control system ensures reliable operation and protects your investment by continually monitoring the operational parameters. Some of the features include,

- Discharge pressure and temperature.

- Total run hours and load hours.

- Service due forall consumables.

- Safety features like high temperature cut-off, Low/high voltage cut-off, Direction control cut-off, High ampere cut-off, two phase protection.

- Accurate fault log monitor. (history of faults and current fault)

- Cooler fan start/stop temperature setting.

- Continuous unload shut-down timer.

SMART COMPRESSOR All compressors are fitted and supplied with loT device for remote monitoring at no extra cost.

LOWER OIL CARRY OVER

Oil separation is done by an efficiently designed tank through oil separation by impact and centrifugal force (OSB1C). This design allows lower pressure drop and increased life of separator element.

CANOPY

Our ergonomically designed canopy and layout allows quick and easy access to service personal with magnetic doors that can be removed in seconds.

SCREW AIR COMPRESSOR COUPLED DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping higher cfm/hp.

VFD SCREW AIR COMPRESSOR COUPLED DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

SCREW AIR COMPRESSOR BELT DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping and higher cfm/hp.

VFD SCREW AIR COMPRES - BELT DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

PERMANENT MAGNET MOTOR

SAVING MORE COST FOR YOU

REDUCING TOTAL OPERATIONAL COST OF AIR COMPRESSOR

The total cost consist of procurement, maintenance and energy cost in the life cycle of air compressor. The energy cost accounts for a considerable proportion. Energy consumption can be lowered by frequency conversion control system, thereby significantly reducing total cost of air compressor.

OTHER ADVANTAGES OF FREQUENCY CONVERSION CONTROL SYSTEM

Stable air pressure: Since stepless speed regulation characteristics of frequency converter are utilized in frequency conversion screw air compressor. Pressure can be quickly adjusted and controlled through controller or PID regulator in inverter. Air pressure stability can be improved exponentially compared with upper and lower limit switch control of power frequency operation.

No impact on startup: Since inverter itself is a soft start device, maximum start current is about twice of rated current and the startup impact is small compared with power frequency startup which is generally several times higher than the rated current. The impact can gradually reduce impact on the power grid and the whole mechanical system.

Low noise and low wear: Since operation frequency during stable operation is smaller than power frequency, mechanical noise is lower and mechanical wear is low.

REFRIGERANT AIR DRYER

BAC Refrigerant Air Dryer models can be used for applications that require ISO 8573-1 Class 4 & Class 5 air quality. Automobile | Cement | Food processing | Injection Moulding | Packaging | Painting | Paper Mills Pet Bottle Industry | Pharmaceutical Industry | Pneumatic Control system | Pneumatic tools & Equipments Rice Sorting | Sand Blasting Textile Industry | Tire Inflation | Power Plants | Steel Plants

SILENT FEATURES

Service

Total modular canopy design, interchangeability, easy fitment of all components and the data from microcontroller ensures preventive maintenance and easy serviceability.

Designed for tropical conditions

Designed and manufactured to suit the high temperature condition by careful sizing of coolers, eveporators and selection of suitable refrigeration. components.

Low Pressure drop

The unique, Indigenously designed 3-in-1 evaporator facilitates low pressure drop lesser than 0.2 bar, while providing maximum heat transfer efficiency.

High Reliability

Reliability is ensured through superior quality parts like high grade, thicker copper tubes and processes like powder coating with 7 tank process etc, and through state-of-the-art safety controls and operation monitoring through unique microprocessor controllers.

AIR FILTERS

Purification of compressed air is needed because the air we breathe carries contaminants. Airborne particles, water, microbes and chemical gases enter compressors and in a compressed state these contaminants become concentrated and more destructive. In the compressed air system, hard particles assault equipment and piping. The result is damage to the system and generation of more particles. Examples of particles found in a compressed air system include desiccant dust, rust, pipe scale, metal oxides and dirt, which can be eliminated by applying proper filteration system.

Use “BAC” Genuine Spares & Accessories for Longer Life

Industrial Reciprocating Air Compressors Suppliers in Howrah

Monoblock Direct Driven Air Compressor

Single Cylinder Belt Driven Air Compressor

Double Cylinder Vertical Tank Air Compressor

Double Cylinder Tank Mounted Air Compressor

Triple Cylinder Tank Mounted Air Compressor

Triple Cylinder Base Mounted Air Compressor

Spare Parts & Accessories

Refrigerant Air Dryer (20 CFM to 1000 CFM)

Air & Oil Filters (35 CFM to 777 CFM)

Auto Drain Valves (Low / High discharge & Float type)

Screw Air Compressor Dealers in Howrah

Refrigerant Air Dryer (20 CFM to 1000 CFM)

BAC BD SERIES

SCREW COMPRESSOR TANK MOUNTED WITH DRYER

AIR END

Belt Driven and Coupling driven are available.

LOWER RUNNING SPEED

All BAC compressors run < 3000rpm which is much lower compared to our competitors. Large air-ends with lower running speed are more efficient than smaller air ends with higher running speeds because they supply more air for the same drive power. This results in higher bearing life, lower energy cost and reduces wear &tear on all the components.

COOLER

Bigger cooling surface area enhances the cooling of air and oil even at an ambient temperature of 55 °C. Smart programming allows cooling fan to start and stop at adjustable temperatures to minimize the energy cost of the motor. All BAC compressor coolers are positioned on top for natural flow of hot air.

PRE FILTERS

BAC compressors are equipped with pre-filter elements which prevents dust entry inside the canopy. This increases the suction filter element life and maintains the cleanliness inside the canopy.

LOWER NOISE

Canopy doors are lined up with high grade foam to keep the compressors as quiet as possible.

CONTROL PANEL

Our control system ensures reliable operation and protects your investment by continually monitoring the operational parameters. Some of the features include,

- Discharge pressure and temperature.

- Total run hours and load hours.

- Service due forall consumables.

- Safety features like high temperature cut-off, Low/high voltage cut-off, Direction control cut-off, High ampere cut-off, two phase protection.

- Accurate fault log monitor. (history of faults and current fault)

- Cooler fan start/stop temperature setting.

- Continuous unload shut-down timer.

SMART COMPRESSOR All compressors are fitted and supplied with loT device for remote monitoring at no extra cost.

LOWER OIL CARRY OVER

Oil separation is done by an efficiently designed tank through oil separation by impact and centrifugal force (OSB1C). This design allows lower pressure drop and increased life of separator element.

CANOPY

Our ergonomically designed canopy and layout allows quick and easy access to service personal with magnetic doors that can be removed in seconds.

SCREW AIR COMPRESSOR COUPLED DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping higher cfm/hp.

VFD SCREW AIR COMPRESSOR COUPLED DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

SCREW AIR COMPRESSOR BELT DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping and higher cfm/hp.

VFD SCREW AIR COMPRES - BELT DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

PERMANENT MAGNET MOTOR

SAVING MORE COST FOR YOU

REDUCING TOTAL OPERATIONAL COST OF AIR COMPRESSOR

The total cost consist of procurement, maintenance and energy cost in the life cycle of air compressor. The energy cost accounts for a considerable proportion. Energy consumption can be lowered by frequency conversion control system, thereby significantly reducing total cost of air compressor.

OTHER ADVANTAGES OF FREQUENCY CONVERSION CONTROL SYSTEM

Stable air pressure:Since stepless speed regulation characteristics of frequency converter are utilized in frequency conversion screw air compressor. Pressure can be quickly adjusted and controlled through controller or PID regulator in inverter. Air pressure stability can be improved exponentially compared with upper and lower limit switch control of power frequency operation.

No impact on startup: Since inverter itself is a soft start device, maximum start current is about twice of rated current and the startup impact is small compared with power frequency startup which is generally several times higher than the rated current. The impact can gradually reduce impact on the power grid and the whole mechanical system.

Low noise and low wear: Since operation frequency during stable operation is smaller than power frequency, mechanical noise is lower and mechanical wear is low.

REFRIGERANT AIR DRYER

BAC Refrigerant Air Dryer models can be used for applications that require ISO 8573-1 Class 4 & Class 5 air quality. Automobile | Cement | Food processing | Injection Moulding | Packaging | Painting | Paper Mills Pet Bottle Industry | Pharmaceutical Industry | Pneumatic Control system | Pneumatic tools & Equipments Rice Sorting | Sand Blasting Textile Industry | Tire Inflation | Power Plants | Steel Plants

SILENT FEATURES

Service

Total modular canopy design, interchangeability, easy fitment of all components and the data from microcontroller ensures preventive maintenance and easy serviceability.

Designed for tropical conditions

Designed and manufactured to suit the high temperature condition by careful sizing of coolers, eveporators and selection of suitable refrigeration. components.

Low Pressure drop

The unique, Indigenously designed 3-in-1 evaporator facilitates low pressure drop lesser than 0.2 bar, while providing maximum heat transfer efficiency.

High Reliability

Reliability is ensured through superior quality parts like high grade, thicker copper tubes and processes like powder coating with 7 tank process etc, and through state-of-the-art safety controls and operation monitoring through unique microprocessor controllers.

AIR FILTERS

Purification of compressed air is needed because the air we breathe carries contaminants. Airborne particles, water, microbes and chemical gases enter compressors and in a compressed state these contaminants become concentrated and more destructive. In the compressed air system, hard particles assault equipment and piping. The result is damage to the system and generation of more particles. Examples of particles found in a compressed air system include desiccant dust, rust, pipe scale, metal oxides and dirt, which can be eliminated by applying proper filteration system.

Use “BAC” Genuine Spares & Accessories for Longer Life

Industrial Reciprocating Air Compressors Suppliers in Haldia

Monoblock Direct Driven Air Compressor

Single Cylinder Belt Driven Air Compressor

Double Cylinder Vertical Tank Air Compressor

Double Cylinder Tank Mounted Air Compressor

Triple Cylinder Tank Mounted Air Compressor

Triple Cylinder Base Mounted Air Compressor

Spare Parts & Accessories

Refrigerant Air Dryer (20 CFM to 1000 CFM)

Air & Oil Filters (35 CFM to 777 CFM)

Auto Drain Valves (Low / High discharge & Float type)

Screw Air Compressor Dealers in Haldia

Refrigerant Air Dryer (20 CFM to 1000 CFM)

BAC BD SERIES

SCREW COMPRESSOR TANK MOUNTED WITH DRYER

AIR END

Belt Driven and Coupling driven are available.

LOWER RUNNING SPEED

All BAC compressors run < 3000rpm which is much lower compared to our competitors. Large air-ends with lower running speed are more efficient than smaller air ends with higher running speeds because they supply more air for the same drive power. This results in higher bearing life, lower energy cost and reduces wear &tear on all the components.

COOLER

Bigger cooling surface area enhances the cooling of air and oil even at an ambient temperature of 55 °C. Smart programming allows cooling fan to start and stop at adjustable temperatures to minimize the energy cost of the motor. All BAC compressor coolers are positioned on top for natural flow of hot air.

PRE FILTERS

BAC compressors are equipped with pre-filter elements which prevents dust entry inside the canopy. This increases the suction filter element life and maintains the cleanliness inside the canopy.

LOWER NOISE

Canopy doors are lined up with high grade foam to keep the compressors as quiet as possible.

CONTROL PANEL

Our control system ensures reliable operation and protects your investment by continually monitoring the operational parameters. Some of the features include,

- Discharge pressure and temperature.

- Total run hours and load hours.

- Service due forall consumables.

- Safety features like high temperature cut-off, Low/high voltage cut-off, Direction control cut-off, High ampere cut-off, two phase protection.

- Accurate fault log monitor. (history of faults and current fault)

- Cooler fan start/stop temperature setting.

- Continuous unload shut-down timer.

SMART COMPRESSOR All compressors are fitted and supplied with loT device for remote monitoring at no extra cost.

LOWER OIL CARRY OVER

Oil separation is done by an efficiently designed tank through oil separation by impact and centrifugal force (OSB1C). This design allows lower pressure drop and increased life of separator element.

CANOPY

Our ergonomically designed canopy and layout allows quick and easy access to service personal with magnetic doors that can be removed in seconds.

SCREW AIR COMPRESSOR COUPLED DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping higher cfm/hp.

VFD SCREW AIR COMPRESSOR COUPLED DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

SCREW AIR COMPRESSOR BELT DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping and higher cfm/hp.

VFD SCREW AIR COMPRES - BELT DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

PERMANENT MAGNET MOTOR

SAVING MORE COST FOR YOU

REDUCING TOTAL OPERATIONAL COST OF AIR COMPRESSOR

The total cost consist of procurement, maintenance and energy cost in the life cycle of air compressor. The energy cost accounts for a considerable proportion. Energy consumption can be lowered by frequency conversion control system, thereby significantly reducing total cost of air compressor.

OTHER ADVANTAGES OF FREQUENCY CONVERSION CONTROL SYSTEM

Stable air pressure: Since stepless speed regulation characteristics of frequency converter are utilized in frequency conversion screw air compressor. Pressure can be quickly adjusted and controlled through controller or PID regulator in inverter. Air pressure stability can be improved exponentially compared with upper and lower limit switch control of power frequency operation.

No impact on startup: Since inverter itself is a soft start device, maximum start current is about twice of rated current and the startup impact is small compared with power frequency startup which is generally several times higher than the rated current. The impact can gradually reduce impact on the power grid and the whole mechanical system.

Low noise and low wear: Since operation frequency during stable operation is smaller than power frequency, mechanical noise is lower and mechanical wear is low.

REFRIGERANT AIR DRYER

BAC Refrigerant Air Dryer models can be used for applications that require ISO 8573-1 Class 4 & Class 5 air quality. Automobile | Cement | Food processing | Injection Moulding | Packaging | Painting | Paper Mills Pet Bottle Industry | Pharmaceutical Industry | Pneumatic Control system | Pneumatic tools & Equipments Rice Sorting | Sand Blasting Textile Industry | Tire Inflation | Power Plants | Steel Plants

SILENT FEATURES

Service

Total modular canopy design, interchangeability, easy fitment of all components and the data from microcontroller ensures preventive maintenance and easy serviceability.

Designed for tropical conditions

Designed and manufactured to suit the high temperature condition by careful sizing of coolers, eveporators and selection of suitable refrigeration. components.

Low Pressure drop

The unique, Indigenously designed 3-in-1 evaporator facilitates low pressure drop lesser than 0.2 bar, while providing maximum heat transfer efficiency.

High Reliability

Reliability is ensured through superior quality parts like high grade, thicker copper tubes and processes like powder coating with 7 tank process etc, and through state-of-the-art safety controls and operation monitoring through unique microprocessor controllers.

AIR FILTERS

Purification of compressed air is needed because the air we breathe carries contaminants. Airborne particles, water, microbes and chemical gases enter compressors and in a compressed state these contaminants become concentrated and more destructive. In the compressed air system, hard particles assault equipment and piping. The result is damage to the system and generation of more particles. Examples of particles found in a compressed air system include desiccant dust, rust, pipe scale, metal oxides and dirt, which can be eliminated by applying proper filteration system.

Use “BAC” Genuine Spares & Accessories for Longer Life

Industrial Reciprocating Air Compressors Suppliers in Barjora

Monoblock Direct Driven Air Compressor

Single Cylinder Belt Driven Air Compressor

Double Cylinder Vertical Tank Air Compressor

Double Cylinder Tank Mounted Air Compressor

Triple Cylinder Tank Mounted Air Compressor

Triple Cylinder Base Mounted Air Compressor

Spare Parts & Accessories

Refrigerant Air Dryer (20 CFM to 1000 CFM)

Air & Oil Filters (35 CFM to 777 CFM)

Auto Drain Valves (Low / High discharge & Float type)

Screw Air Compressor Dealers in Barjora

Refrigerant Air Dryer (20 CFM to 1000 CFM)

BAC BD SERIES

SCREW COMPRESSOR TANK MOUNTED WITH DRYER

AIR END

Belt Driven and Coupling driven are available.

LOWER RUNNING SPEED

All BAC compressors run < 3000rpm which is much lower compared to our competitors. Large air-ends with lower running speed are more efficient than smaller air ends with higher running speeds because they supply more air for the same drive power. This results in higher bearing life, lower energy cost and reduces wear &tear on all the components.

COOLER

Bigger cooling surface area enhances the cooling of air and oil even at an ambient temperature of 55 °C. Smart programming allows cooling fan to start and stop at adjustable temperatures to minimize the energy cost of the motor. All BAC compressor coolers are positioned on top for natural flow of hot air.

PRE FILTERS

BAC compressors are equipped with pre-filter elements which prevents dust entry inside the canopy. This increases the suction filter element life and maintains the cleanliness inside the canopy.

LOWER NOISE

Canopy doors are lined up with high grade foam to keep the compressors as quiet as possible.

CONTROL PANEL

Our control system ensures reliable operation and protects your investment by continually monitoring the operational parameters. Some of the features include,

- Discharge pressure and temperature.

- Total run hours and load hours.

- Service due forall consumables.

- Safety features like high temperature cut-off, Low/high voltage cut-off, Direction control cut-off, High ampere cut-off, two phase protection.

- Accurate fault log monitor. (history of faults and current fault)

- Cooler fan start/stop temperature setting.

- Continuous unload shut-down timer.

SMART COMPRESSOR All compressors are fitted and supplied with loT device for remote monitoring at no extra cost.

LOWER OIL CARRY OVER

Oil separation is done by an efficiently designed tank through oil separation by impact and centrifugal force (OSB1C). This design allows lower pressure drop and increased life of separator element.

CANOPY

Our ergonomically designed canopy and layout allows quick and easy access to service personal with magnetic doors that can be removed in seconds.

SCREW AIR COMPRESSOR COUPLED DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping higher cfm/hp.

VFD SCREW AIR COMPRESSOR COUPLED DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

SCREW AIR COMPRESSOR BELT DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping and higher cfm/hp.

VFD SCREW AIR COMPRES - BELT DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

PERMANENT MAGNET MOTOR

SAVING MORE COST FOR YOU

REDUCING TOTAL OPERATIONAL COST OF AIR COMPRESSOR

The total cost consist of procurement, maintenance and energy cost in the life cycle of air compressor. The energy cost accounts for a considerable proportion. Energy consumption can be lowered by frequency conversion control system, thereby significantly reducing total cost of air compressor.

OTHER ADVANTAGES OF FREQUENCY CONVERSION CONTROL SYSTEM

Stable air pressure: Since stepless speed regulation characteristics of frequency converter are utilized in frequency conversion screw air compressor. Pressure can be quickly adjusted and controlled through controller or PID regulator in inverter. Air pressure stability can be improved exponentially compared with upper and lower limit switch control of power frequency operation.

No impact on startup: Since inverter itself is a soft start device, maximum start current is about twice of rated current and the startup impact is small compared with power frequency startup which is generally several times higher than the rated current. The impact can gradually reduce impact on the power grid and the whole mechanical system.

Low noise and low wear: Since operation frequency during stable operation is smaller than power frequency, mechanical noise is lower and mechanical wear is low.

REFRIGERANT AIR DRYER

BAC Refrigerant Air Dryer models can be used for applications that require ISO 8573-1 Class 4 & Class 5 air quality. Automobile | Cement | Food processing | Injection Moulding | Packaging | Painting | Paper Mills Pet Bottle Industry | Pharmaceutical Industry | Pneumatic Control system | Pneumatic tools & Equipments Rice Sorting | Sand Blasting Textile Industry | Tire Inflation | Power Plants | Steel Plants

SILENT FEATURES

Service

Total modular canopy design, interchangeability, easy fitment of all components and the data from microcontroller ensures preventive maintenance and easy serviceability.

Designed for tropical conditions

Designed and manufactured to suit the high temperature condition by careful sizing of coolers, eveporators and selection of suitable refrigeration. components.

Low Pressure drop

The unique, Indigenously designed 3-in-1 evaporator facilitates low pressure drop lesser than 0.2 bar, while providing maximum heat transfer efficiency.

High Reliability

Reliability is ensured through superior quality parts like high grade, thicker copper tubes and processes like powder coating with 7 tank process etc, and through state-of-the-art safety controls and operation monitoring through unique microprocessor controllers.

AIR FILTERS

Purification of compressed air is needed because the air we breathe carries contaminants. Airborne particles, water, microbes and chemical gases enter compressors and in a compressed state these contaminants become concentrated and more destructive. In the compressed air system, hard particles assault equipment and piping. The result is damage to the system and generation of more particles. Examples of particles found in a compressed air system include desiccant dust, rust, pipe scale, metal oxides and dirt, which can be eliminated by applying proper filteration system.

Use “BAC” Genuine Spares & Accessories for Longer Life

Industrial Reciprocating Air Compressors Suppliers in Bardhaman

Monoblock Direct Driven Air Compressor

Single Cylinder Belt Driven Air Compressor

Double Cylinder Vertical Tank Air Compressor

Double Cylinder Tank Mounted Air Compressor

Triple Cylinder Tank Mounted Air Compressor

Triple Cylinder Base Mounted Air Compressor

Spare Parts & Accessories

Refrigerant Air Dryer (20 CFM to 1000 CFM)

Air & Oil Filters (35 CFM to 777 CFM)

Auto Drain Valves (Low / High discharge & Float type)

Screw Air Compressor Dealers in Bardhaman

Refrigerant Air Dryer (20 CFM to 1000 CFM)

BAC BD SERIES

SCREW COMPRESSOR TANK MOUNTED WITH DRYER

AIR END

Belt Driven and Coupling driven are available.

LOWER RUNNING SPEED

All BAC compressors run < 3000rpm which is much lower compared to our competitors. Large air-ends with lower running speed are more efficient than smaller air ends with higher running speeds because they supply more air for the same drive power. This results in higher bearing life, lower energy cost and reduces wear &tear on all the components.

COOLER

Bigger cooling surface area enhances the cooling of air and oil even at an ambient temperature of 55 °C. Smart programming allows cooling fan to start and stop at adjustable temperatures to minimize the energy cost of the motor. All BAC compressor coolers are positioned on top for natural flow of hot air.

PRE FILTERS

BAC compressors are equipped with pre-filter elements which prevents dust entry inside the canopy. This increases the suction filter element life and maintains the cleanliness inside the canopy.

LOWER NOISE

Canopy doors are lined up with high grade foam to keep the compressors as quiet as possible.

CONTROL PANEL

Our control system ensures reliable operation and protects your investment by continually monitoring the operational parameters. Some of the features include,

- Discharge pressure and temperature.

- Total run hours and load hours.

- Service due forall consumables.

- Safety features like high temperature cut-off, Low/high voltage cut-off, Direction control cut-off, High ampere cut-off, two phase protection.

- Accurate fault log monitor. (history of faults and current fault)

- Cooler fan start/stop temperature setting.

- Continuous unload shut-down timer.

SMART COMPRESSOR All compressors are fitted and supplied with loT device for remote monitoring at no extra cost.

LOWER OIL CARRY OVER

Oil separation is done by an efficiently designed tank through oil separation by impact and centrifugal force (OSB1C). This design allows lower pressure drop and increased life of separator element.

CANOPY

Our ergonomically designed canopy and layout allows quick and easy access to service personal with magnetic doors that can be removed in seconds.

SCREW AIR COMPRESSOR COUPLED DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping higher cfm/hp.

VFD SCREW AIR COMPRESSOR COUPLED DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

SCREW AIR COMPRESSOR BELT DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping and higher cfm/hp.

VFD SCREW AIR COMPRES - BELT DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

PERMANENT MAGNET MOTOR

SAVING MORE COST FOR YOU

REDUCING TOTAL OPERATIONAL COST OF AIR COMPRESSOR

The total cost consist of procurement, maintenance and energy cost in the life cycle of air compressor. The energy cost accounts for a considerable proportion. Energy consumption can be lowered by frequency conversion control system, thereby significantly reducing total cost of air compressor.

OTHER ADVANTAGES OF FREQUENCY CONVERSION CONTROL SYSTEM

Stable air pressure: Since stepless speed regulation characteristics of frequency converter are utilized in frequency conversion screw air compressor. Pressure can be quickly adjusted and controlled through controller or PID regulator in inverter. Air pressure stability can be improved exponentially compared with upper and lower limit switch control of power frequency operation.

No impact on startup: Since inverter itself is a soft start device, maximum start current is about twice of rated current and the startup impact is small compared with power frequency startup which is generally several times higher than the rated current. The impact can gradually reduce impact on the power grid and the whole mechanical system.

Low noise and low wear: Since operation frequency during stable operation is smaller than power frequency, mechanical noise is lower and mechanical wear is low.

REFRIGERANT AIR DRYER

BAC Refrigerant Air Dryer models can be used for applications that require ISO 8573-1 Class 4 & Class 5 air quality. Automobile | Cement | Food processing | Injection Moulding | Packaging | Painting | Paper Mills Pet Bottle Industry | Pharmaceutical Industry | Pneumatic Control system | Pneumatic tools & Equipments Rice Sorting | Sand Blasting Textile Industry | Tire Inflation | Power Plants | Steel Plants

SILENT FEATURES

Service

Total modular canopy design, interchangeability, easy fitment of all components and the data from microcontroller ensures preventive maintenance and easy serviceability.

Designed for tropical conditions

Designed and manufactured to suit the high temperature condition by careful sizing of coolers, eveporators and selection of suitable refrigeration. components.

Low Pressure drop

The unique, Indigenously designed 3-in-1 evaporator facilitates low pressure drop lesser than 0.2 bar, while providing maximum heat transfer efficiency.

High Reliability

Reliability is ensured through superior quality parts like high grade, thicker copper tubes and processes like powder coating with 7 tank process etc, and through state-of-the-art safety controls and operation monitoring through unique microprocessor controllers.

AIR FILTERS

Purification of compressed air is needed because the air we breathe carries contaminants. Airborne particles, water, microbes and chemical gases enter compressors and in a compressed state these contaminants become concentrated and more destructive. In the compressed air system, hard particles assault equipment and piping. The result is damage to the system and generation of more particles. Examples of particles found in a compressed air system include desiccant dust, rust, pipe scale, metal oxides and dirt, which can be eliminated by applying proper filteration system.

Use “BAC” Genuine Spares & Accessories for Longer Life

Industrial Reciprocating Air Compressors Suppliers in Bantala

Monoblock Direct Driven Air Compressor

Single Cylinder Belt Driven Air Compressor

Double Cylinder Vertical Tank Air Compressor

Double Cylinder Tank Mounted Air Compressor

Triple Cylinder Tank Mounted Air Compressor

Triple Cylinder Base Mounted Air Compressor

Spare Parts & Accessories

Refrigerant Air Dryer (20 CFM to 1000 CFM)

Air & Oil Filters (35 CFM to 777 CFM)

Auto Drain Valves (Low / High discharge & Float type)

Screw Air Compressor Dealers in Bantala

Refrigerant Air Dryer (20 CFM to 1000 CFM)

BAC BD SERIES

SCREW COMPRESSOR TANK MOUNTED WITH DRYER

AIR END

Belt Driven and Coupling driven are available.

LOWER RUNNING SPEED

All BAC compressors run < 3000rpm which is much lower compared to our competitors. Large air-ends with lower running speed are more efficient than smaller air ends with higher running speeds because they supply more air for the same drive power. This results in higher bearing life, lower energy cost and reduces wear &tear on all the components.

COOLER

Bigger cooling surface area enhances the cooling of air and oil even at an ambient temperature of 55 °C. Smart programming allows cooling fan to start and stop at adjustable temperatures to minimize the energy cost of the motor. All BAC compressor coolers are positioned on top for natural flow of hot air.

PRE FILTERS

BAC compressors are equipped with pre-filter elements which prevents dust entry inside the canopy. This increases the suction filter element life and maintains the cleanliness inside the canopy.

LOWER NOISE

Canopy doors are lined up with high grade foam to keep the compressors as quiet as possible.

CONTROL PANEL

Our control system ensures reliable operation and protects your investment by continually monitoring the operational parameters. Some of the features include,

- Discharge pressure and temperature.

- Total run hours and load hours.

- Service due forall consumables.

- Safety features like high temperature cut-off, Low/high voltage cut-off, Direction control cut-off, High ampere cut-off, two phase protection.

- Accurate fault log monitor. (history of faults and current fault)

- Cooler fan start/stop temperature setting.

- Continuous unload shut-down timer.

SMART COMPRESSOR All compressors are fitted and supplied with loT device for remote monitoring at no extra cost.

LOWER OIL CARRY OVER

Oil separation is done by an efficiently designed tank through oil separation by impact and centrifugal force (OSB1C). This design allows lower pressure drop and increased life of separator element.

CANOPY

Our ergonomically designed canopy and layout allows quick and easy access to service personal with magnetic doors that can be removed in seconds.

SCREW AIR COMPRESSOR COUPLED DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping higher cfm/hp.

VFD SCREW AIR COMPRESSOR COUPLED DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

SCREW AIR COMPRESSOR BELT DRIVEN

BAC compressor has been designed for heavy duty applications and features low speed air end operation, higher lifetime of components, rigid piping and higher cfm/hp.

VFD SCREW AIR COMPRES - BELT DRIVEN

- Highly efficient permanent magnet asynchronous motor with soft start design.

- High temperature resistance rare earth permanent magnet is adopted to ensure no demagnetization.

- The motor has higher torque, higher power factor and lower power dissipation. Due to this it 5-8% more efficient than an ordinary motor.

- The motor load can vary from 25% to 100% of the original load which is wide and motor efficiency is almost constant under different loads.

PERMANENT MAGNET MOTOR

SAVING MORE COST FOR YOU

REDUCING TOTAL OPERATIONAL COST OF AIR COMPRESSOR

The total cost consist of procurement, maintenance and energy cost in the life cycle of air compressor. The energy cost accounts for a considerable proportion. Energy consumption can be lowered by frequency conversion control system, thereby significantly reducing total cost of air compressor.

OTHER ADVANTAGES OF FREQUENCY CONVERSION CONTROL SYSTEM

Stable air pressure:Since stepless speed regulation characteristics of frequency converter are utilized in frequency conversion screw air compressor. Pressure can be quickly adjusted and controlled through controller or PID regulator in inverter. Air pressure stability can be improved exponentially compared with upper and lower limit switch control of power frequency operation.

No impact on startup:Since inverter itself is a soft start device, maximum start current is about twice of rated current and the startup impact is small compared with power frequency startup which is generally several times higher than the rated current. The impact can gradually reduce impact on the power grid and the whole mechanical system.

Low noise and low wear: Since operation frequency during stable operation is smaller than power frequency, mechanical noise is lower and mechanical wear is low.

REFRIGERANT AIR DRYER

BAC Refrigerant Air Dryer models can be used for applications that require ISO 8573-1 Class 4 & Class 5 air quality. Automobile | Cement | Food processing | Injection Moulding | Packaging | Painting | Paper Mills Pet Bottle Industry | Pharmaceutical Industry | Pneumatic Control system | Pneumatic tools & Equipments Rice Sorting | Sand Blasting Textile Industry | Tire Inflation | Power Plants | Steel Plants

SILENT FEATURES

Service

Total modular canopy design, interchangeability, easy fitment of all components and the data from microcontroller ensures preventive maintenance and easy serviceability.

Designed for tropical conditions

Designed and manufactured to suit the high temperature condition by careful sizing of coolers, eveporators and selection of suitable refrigeration. components.

Low Pressure drop

The unique, Indigenously designed 3-in-1 evaporator facilitates low pressure drop lesser than 0.2 bar, while providing maximum heat transfer efficiency.

High Reliability

Reliability is ensured through superior quality parts like high grade, thicker copper tubes and processes like powder coating with 7 tank process etc, and through state-of-the-art safety controls and operation monitoring through unique microprocessor controllers.

AIR FILTERS

Purification of compressed air is needed because the air we breathe carries contaminants. Airborne particles, water, microbes and chemical gases enter compressors and in a compressed state these contaminants become concentrated and more destructive. In the compressed air system, hard particles assault equipment and piping. The result is damage to the system and generation of more particles. Examples of particles found in a compressed air system include desiccant dust, rust, pipe scale, metal oxides and dirt, which can be eliminated by applying proper filteration system.

Use “BAC” Genuine Spares & Accessories for Longer Life