Production of liquid medical oxygen using screw compressors in PSA oxygen generator

BAC Compressor is the leading manufacturer of screw compressors and the compressors are equipped with a microcontroller for efficient oxygen production. The produced oxygen can be stored in oxygen cylinders and transported to the desired medical facilities. BAC compressor’s screw compressors are highly competent and play a vital role in the production of oxygen. Highly pure Oxygen gas of 93-95% purity can be produced using this method.

- Capacity of Module : 30 Nm3 /hr.

- Gas Produced : Oxygen

- Operating temperature : 0 Deg C to 50 Deg C

- ZMS Type : CECA FRANCE

- Atm. Dew Point : minus 40 degree C

- Outlet Pressure : 6 BarG

- Compressed Air requirement : 360 Nm3/hr. @ 7 Barg

- Oxygen Gas Analyzer (Online) : Digital – Provided with 2 Alarms

- Operation : HMI – Automatic with PLC

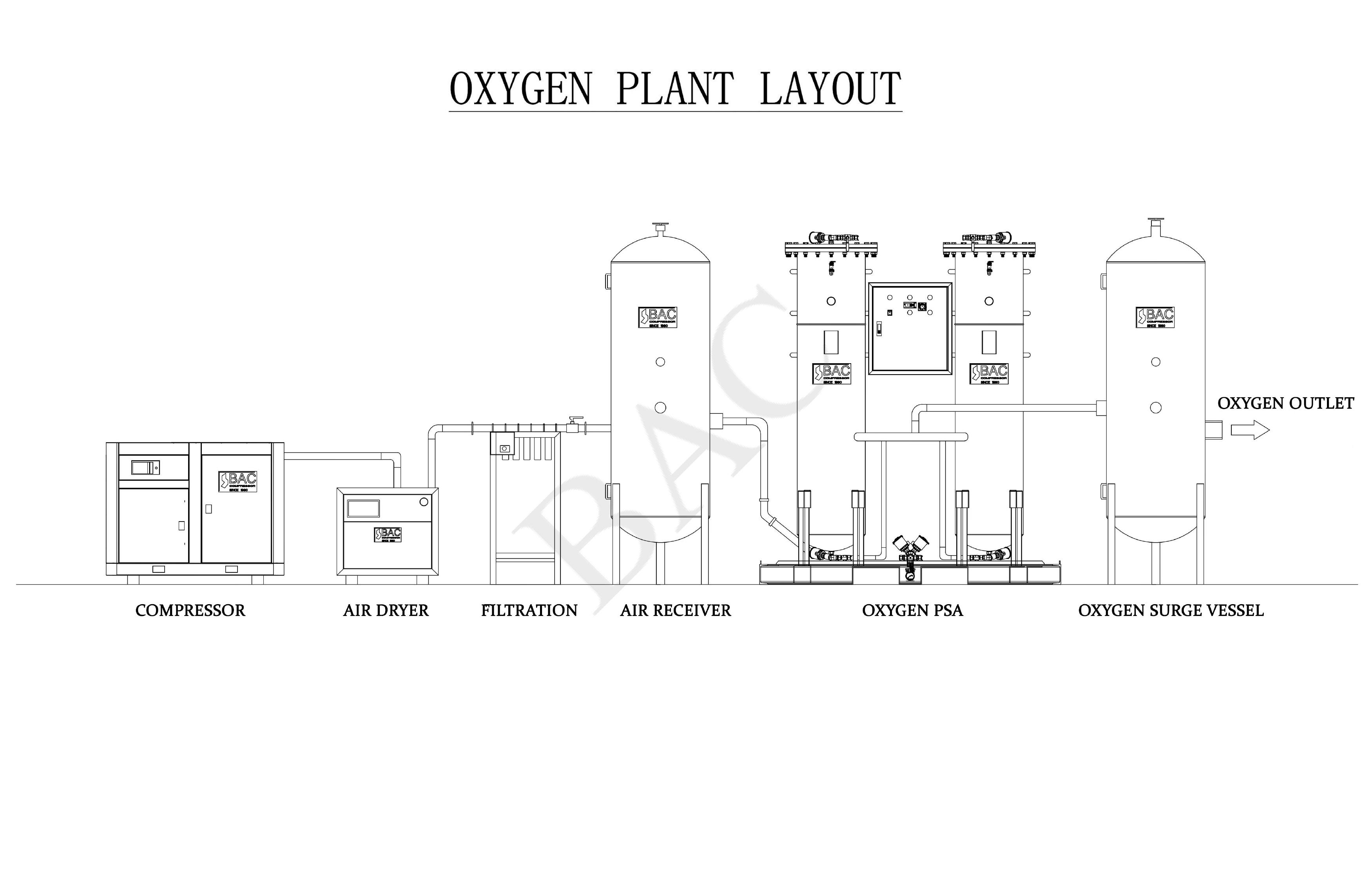

Process Description of PSA Oxygen Plant

From atmospheric air, the production of Oxygen gas is based on the Pressure Swing Adsorption(PSA) principle by adsorption of oxygen gas using a special grade of imported Zeolite Molecular Sieves (ZMS). Atmospheric air is compressed by a screw compressor to a pressure of 7.5 kg /cm2g and cooled by Air Cooler. The condensed moisture shall be removed out automatically from the air receiver by an automatic drain valve.

At constant pressure, the compressed air is passed through the twin tower PSA module packed with special grade molecular sieves. The entire operation is automated and is controlled by a sequence programmer, quick change over valves. Raw Oxygen gas of 93-95% purity at 4.5-6 Kg/cm2g pressure and having a Dew point of -40 deg C is produced by the PSA Unit. The produced oxygen flows to a surge vessel to balance the fluctuations in pressure and concentration, which can then be stored and transported.

- Capacity : 2 – 1,000 Nm3/hr

- Oxygen Purity : 93% (+ / -3%)

- Oxygen Gas Pressure: 4 – 150 Bar (g)

Advantages

- Compact in size, Occupies lesser space.

- Electricity is the only consumable.

- Low production cost of Oxygen per Nm3

- Easy to operate. It is a single button start machine.

- No need for separate operators.

- Auto on/off based on the oxygen consumption.

- Continuous on line monitoring of Oxygen purity.

The Oxygen Generator functions on Pressure Swing Adsorption technology, commonly known as P S A Technology. PSA Technology is based on the selective adsorption phenomena of gas molecules under pressure on the surface of a highly porous and efficient adsorbent. In the case of Medical Oxygen Generators, the adsorbent used is Zeolite based Molecular Sieve (Z.M.S.). In PSA System when compressed air is passed through an adsorption tower field with Z.M.S, the molecules of Carbon Di Oxide, Nitrogen, moisture & other unwanted gases are adsorbed on the surface of Z.M.S. Oxygen is not adsorbed by Z.M.S, therefore it comes out of the adsorption tower and is collected in a surge vessel. For the continuous generation of Oxygen, two Adsorption towers are provided and these two are interconnected with Auto-change over valves controlled by PLC in the control panel. When one of the towers is saturated with oxygen, then the process automatically changes over to another tower and thus the Oxygen production is consistent.

Our systems are the most reliable ones in the industry to assure the highest efficiency, user-friendly design, Economical value and Durability. Our screw compressors for Medical Oxygen Generators can be custom made as per your requirements.