Helpful Tips for Maintenance of Air Compressors

Proper maintenance of an air reciprocating compressor is necessary to ensure that it functions smoothly and is safe to use. Compressors that are not maintained properly can stop functioning and can also jeopardize your safety while using it. If you have an air compressor, you need to know how to effectively maintain the device.

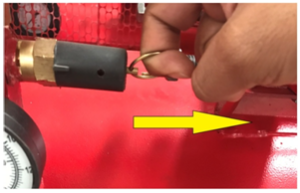

Safety Valve

The pop off valve or safety valve is a small component on the control unit that automatically releases the air from the tank if the pressure in the tank exceeds the preset maximum. This prevents the tank from bursting due to high pressure. In order to ensure that it’s functioning properly, you must check it weekly by pulling the safety valve so that it pops back to its original place. It must release air from the tank at any given time and must pop back at around 40-50 PSI. If it does not do this, it must be replaced.

Oil Change

Make sure that the oil level does not go below the red circle or dot on the oil level sight glass. The oil must be changed every month or at the 500 hour mark. To change oil, you will need to:

- Run the unit for a little while and allow the oil to warm up

- Unplug the unit

- Hold a container under the pump end

- Remove the oil drain plug and allow the oil to collect in the container

- Replace the drain plug

- Fill the crankcase with new oil

You will need to use SAE grade 40 air compressor oil. We recommend Servo press 150 compressor oil. Do not use motor oil as it could block valves and reduce the life of the unit. Running the compressor without oil or low oil will automatically default warranty so you must often check the oil level.

Filter

Usually, every air compressor has a air filter installed on the intake opening. However, if yours does not then you need to install one. You must check the air filter on a regular basis. You can do this by removing the air filter housing cover. If the filter is dirty then you must have it replaced to ensure smooth functioning of the unit. Choked air filters will reduce the suction and efficiency of the air compressor.

Drain the Tank

Many users forget to drain the tank after using the unit. This can lead to rust build up inside the tank. You must always drain moisture from the tank by opening the drain valve at the bottom of the tank. Long periods without draining will reduce the effective air storage capacity in the tank and can also reduce the life span of the air receiver significantly.

Cleaning

You must make sure you keep your air compressor clean at all times. You should clean debris off from the motor, flywheel, tank, airlines and pump cooling fins. Most compressors are air cooled and any form of dust or other deposits will inhibit the effective heat transfer from compressor to the surrounding resulting in higher temperature run. All this must be done while the unit is unplugged.

Noise

Frequently check the compressor from unusual noise. If any rattling sound is heard make sure to tighten all the fasteners as they tend to loosen up in due time. If a squealing noise is heard, you must tighten dive belts or replace drive belts if your compressor is belt driven. Any air leaks must be immediately addressed or it will make the compressor run continuously. Air leak from tanks are very dangerous and compressor must be stopped immediately.

Pressure Switch

Make sure to check your pressure switch is still working in the set range. Many low quality pressure switches tend to lose their accuracy in time. Refer the pressure dial or gauge on the tank and note the pressure at which the compressor stops, then release the air from the tank and note the pressure when the compressor restarts. Compare them with the manufacturers setting and contact any compressor service mechanic to recalibrate if necessary.

Storage

When not in use, the air compressor must be stored in a cool, dry place. The tank must be drained of all moisture. Crank case must be drained of all oil. Disconnect all the pipes and hang them with the open ends down to drain any moisture that could still be present in them.

If you are in search for a reliable and professional provider of reciprocating air compressors, BAC Compressor is the perfect site to consider and visit. We can greatly help you in choosing for the best air compressor that will suit with your needs, expectations and budget.